Hi guys in this article we discuss the topic What is Fastening? Material and Tools Used , so we discuss the some important points related to this article fastening definition, which material is used , types of fasteners, tools used in fasteners, and permanent fasteners. Let's discuss with point wise information to understand simple way,

What is fastening?

Fastening refers to the process of joining or securing two or more objects together. It involves the use of various devices or techniques to hold objects in place, preventing them from moving or separating. Fasteners are essential components in construction, manufacturing, engineering, and everyday applications.

What is Fastening? Material and Tools Used

Fasteners come in different forms, each suited for specific purposes and materials. Common types of fasteners:

Screws: Screws are cylindrical rods with a threaded body and a head that allows for turning with a screwdriver or other tools. They are used to hold objects together by creating a threaded connection with the material they are driven into. Screws can be made of various materials, such as metal or plastic, and are available in different sizes and designs to accommodate specific applications

Nails: Nails are slender metal pins with a sharp point at one end and a flat or rounded head at the other. They are typically driven into wood or other soft materials using a hammer or nail gun. Nails provide strong and reliable fastening for construction, carpentry, and woodworking projects.

Bolts: Bolts are similar to screws but usually larger in size and designed to be used with a nut. They have a threaded body and a head that can be hexagonal or square-shaped for easy turning using a wrench or spanner. Bolts provide secure and durable fastening for heavy-duty applications that require high strength and load-bearing capabilities.

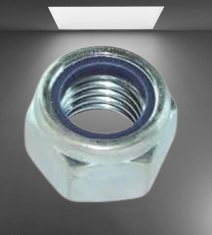

Nuts: Nuts are small metal objects with a threaded hole that corresponds to the thread of a bolt. They are used in conjunction with bolts to create a threaded connection. By tightening the nut onto the bolt, objects can be firmly held together. Nuts are available in various shapes and designs, including hexagonal, square, and winged nuts.

Rivets: Rivets are permanent fasteners that consist of a cylindrical shaft and a head. They are commonly used in metalworking, aerospace, and automotive industries. Rivets are inserted through aligned holes in two or more materials and then deformed or "set" to secure the parts together. This deformation creates a strong, permanent bond.

Adhesives: While not traditional mechanical fasteners, adhesives are substances used to join objects together by forming a bond between their surfaces. Adhesives can be in the form of liquid, tape, or other formulations, and they provide versatile and efficient fastening solutions for various materials, including metal, plastic, and wood.

Fasteners play a critical role in ensuring the integrity,

strength, and safety of assembled structures and components. The choice of

fastening method depends on factors such as the materials being joined, the

required strength, the ease of installation, and the intended application.

What is fastening of a material?

Fastening of a material refers to the process of securing or joining two or more materials together using various fastening methods or devices. The purpose of fastening is to create a stable and reliable connection between the materials, preventing them from moving or separating under the applied loads or forces.

Fastening is essential in a wide range of industries and applications, including construction, manufacturing, engineering, automotive, aerospace, furniture assembly, and many others. It enables the creation of structures, products, and systems by securely joining different components or parts.

The choice of fastening method depends on several factors, including the type of materials being joined, the strength requirements, the environmental conditions, the desired permanence or reversibility of the connection, and the specific application. Some commonly used fastening methods include screws, bolts and nuts, rivets, adhesive bonding, welding, clamps, staples, and hook and loop fasteners, among others.

Proper selection and application of the appropriate fastening method are crucial to ensure the integrity, safety, and longevity of the assembled materials or structures. It is important to consider factors such as load-bearing capacity, corrosion resistance, temperature resistance, ease of installation, and maintenance requirements when choosing the suitable fastening method for a particular application.

Types of fastening

Some additional types of fastening methods:

Welding: Welding is a process of joining two or more metal pieces together by melting the materials and allowing them to fuse. It creates a strong and permanent bond. Welding techniques include arc welding, MIG welding, TIG welding, and spot welding, among others.

Adhesive Bonding: Adhesive bonding involves using specialized adhesives or glues to join materials together. Adhesives can bond a wide range of materials, including metals, plastics, ceramics, and composites. This method provides excellent bonding strength and can distribute stress evenly across the joint.

Clamps: Clamps are devices used to hold objects together by applying pressure. They are typically adjustable and can be tightened to secure the objects in place. Clamps are commonly used in woodworking, metalworking, and other applications where temporary fastening is required.

Hook and Loop Fasteners: Hook and loop fasteners, commonly known as Velcro, consist of two components: hooks and loops. The hooks and loops interlock when pressed together and provide a reversible and reusable fastening solution. Hook and loop fasteners are frequently used in clothing, bags, and other applications where easy opening and closing are desired.

Snap Fasteners: Snap fasteners, also called press studs or poppers, are used to fasten two materials together by using interlocking discs or buttons. They are commonly found in clothing, accessories, and upholstery.

Latches and Catches: Latches and catches are mechanisms used to hold doors, cabinets, and other objects closed. They typically consist of a movable component, such as a lever or a hook, that engages with a fixed component to secure the object. Latches and catches come in various designs, including spring-loaded, magnetic, and friction-based.

Rivets: As mentioned earlier, rivets are fasteners that create a permanent joint by deforming the shaft to secure two or more materials together. They are commonly used in the construction of aircraft, automobiles, and other applications where a high-strength, vibration-resistant connection is needed.

Staples: Staples are thin, U-shaped metal fasteners used to secure materials together by penetrating and bending inward. They are commonly used in offices, upholstery, carpentry, and construction applications.

These are just a few examples of fastening methods available. The choice of fastening technique depends on the specific requirements of the application, such as strength, permanence, reversibility, and ease of installation.

What is the most used fastening?

The most used fastening method can vary depending on the industry, application, and specific requirements. Some of the most commonly used fasteners across a wide range of applications include:

Screws: Screws are versatile and widely used fasteners. They are used in construction, furniture assembly, machinery, electronics, and various other industries. Screws provide a secure and adjustable connection and are available in a wide range of sizes and types to accommodate different materials and applications.

Bolts and Nuts: Bolts and nuts are extensively used in construction, automotive, machinery, and industrial applications that require high strength and load-bearing capabilities. They provide a strong and durable connection, especially for applications that experience heavy loads or vibrations.

Rivets: Rivets are commonly used in the aerospace, automotive, and metalworking industries. They provide a permanent and robust connection, especially for joining metal components. Rivets are often used where welding or other fastening methods may not be feasible or practical.

Adhesive Bonding: Adhesive bonding is widely used across various industries, including automotive, aerospace, electronics, and construction. Adhesives offer excellent bonding strength, flexibility, and the ability to join different types of materials, such as metal, plastic, and composites.

Welding: Welding is extensively used in industries such as construction, automotive, manufacturing, and fabrication. It provides a strong and permanent bond between metal components. Different welding techniques, such as arc welding, MIG welding, and TIG welding, are used depending on the specific application and materials involved.

It's important to note that the most used fastening method can vary depending on the specific industry, application requirements, and technological advancements. Additionally, advancements in materials, technologies, and fastening systems continually contribute to the development and adoption of new fastening methods.

What is fastening tools?

Fastening tools are specialized instruments or equipment used to facilitate the process of fastening materials together. These tools are designed to assist in the installation, tightening, or removal of fasteners.

What is Fastening? Material and Tools Used

Screwdriver: A screwdriver is a handheld tool with a handle and a shaft that fits into the head of a screw. It is used to drive screws into or remove screws from materials. Screwdrivers come in various sizes and types, including flathead, Phillips, and Torx, to accommodate different screw designs.

Wrenches and Spanners: Wrenches, also known as spanners, are tools used to tighten or loosen nuts and bolts. They typically have a handle and a jaw or socket that fits over the fastener. Common types of wrenches include adjustable wrenches, open-end wrenches, box-end wrenches, and socket wrenches.

Pliers: Pliers are versatile hand tools used for gripping, bending, and manipulating objects, including fasteners. They come in various types, such as slip-joint pliers, locking pliers (e.g., Vise-Grips), and needle-nose pliers, and they can be useful for holding or turning fasteners in tight spaces.

Nut Drivers: Nut drivers are hand tools designed to tighten or loosen nuts. They resemble screwdrivers but have a socket-like end that matches the size and shape of the nut. Nut drivers provide a secure grip on the nut while turning it, making it easier to fasten or remove.

Impact Drivers and Wrenches: Impact drivers and impact wrenches are power tools used for driving screws, bolts, and nuts with high torque. They apply concussive rotational forces to help quickly install or remove fasteners. Impact drivers are commonly used for smaller screws, while impact wrenches are used for larger bolts or nuts.

Rivet Guns: Rivet guns are pneumatic or hand-operated tools used for installing rivets. They provide the force necessary to deform the rivet and secure materials together. Rivet guns are available in various sizes and styles to accommodate different rivet types and applications.

Staple Guns: Staple guns are tools used to drive staples into materials, such as fabric, wood, or insulation. They are commonly used in upholstery, construction, and carpentry projects. Staple guns can be manual or powered, and they come in different sizes and designs for specific applications.

These are just a few examples of fastening tools commonly

used for various fastening methods. The specific tools required depend on the

type of fastener, the application, and the desired level of precision and efficiency.

It's important to select the appropriate tool for the task to ensure proper

installation, tightening, or removal of fasteners.

What is permanent fastening?

Permanent fastening refers to the process of joining two or more materials together in a way that creates a long-lasting, durable, and irreversible connection. The objective of permanent fastening is to create a strong and reliable bond that cannot be easily undone without causing damage to the materials or the fastening itself.

Permanent fastening methods are typically used when a secure and lasting connection is required, and disassembly or removal of the fastened components is not anticipated or desired. Permanent fastening is commonly employed in applications where strength, stability, and resistance to external forces or vibrations are critical.

Examples of permanent fastening methods include:

Welding: Welding is a permanent fastening technique that involves melting and fusing materials together. It creates a strong bond between the joined components by using high heat to melt the base materials and a filler material, if necessary. Once cooled, the materials solidify, resulting in a permanent joint.

Adhesive Bonding: Adhesive bonding involves the use of specialized adhesives or glues to create a strong and permanent bond between materials. Adhesives penetrate the surfaces and chemically or mechanically adhere to them, creating a durable connection. Once the adhesive cures or sets, the bond becomes permanent.

Riveting: Riveting is a method of permanent fastening that involves deforming a rivet to create a mechanical connection between materials. The rivet is inserted through aligned holes in the materials, and its tail end is deformed or "set" to secure the joint. Rivets provide a reliable and permanent bond, particularly in metal-to-metal applications.

Permanent Screws: Certain types of screws, such as self-tapping or thread-forming screws, can create a permanent fastening when driven into materials. These screws create their own threads within the materials, resulting in a tight and secure connection that is not easily reversible.

Permanent fastening methods are chosen when the joint is intended to remain intact for the lifespan of the assembly or structure. They are commonly used in industries such as construction, automotive manufacturing, aerospace, and heavy machinery, where strong and durable connections are crucial for safety, stability, and performance.

So in this article we discussed the topic What is Fastening? Material and Tools Used hope you understand best.

Any question or any query comment below. Thanks for reading.

.jpg)