In this lecture we discuss about new topic What is in Straddle milling - Mechanical engineering so without wasting of time lets see about Straddle milling,

Straddle milling- Mechanical engineering

Milling

Milling is the process of producing complex and flat shapes with using of cutting tool. Milling machines are superior to accuracy and surface finish.

When two or more similar perpendicular surfaces are machined at one cut and the operation is called straddle milling.

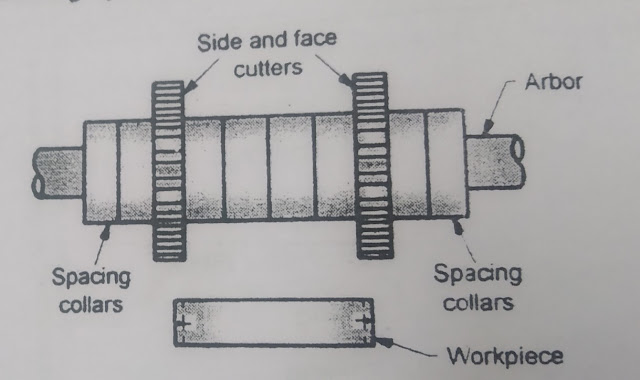

Straddle milling cons ummate by mounting two side milling cutters on the coupled arbor, set apart at an exact spacing. Straddle milling is the opration Producing Flat perpendicular surfaces on both edge of the workpiece by using two side milling cutter mounted on coupled arbor. Two sides of the workpiece are constructed final width dimensions are controlled. Straddle milling posses applications introduction to machining. By using straddle mills of equal diameters parallel slots of equal depth can be milled.

Straddle milling two side milling cutter disparate by spacers, washers, and shims so that the distance between the cutting teeth of each cutter is exactly equal to width of workpiece area needed.

|

| Straddle milling - Mechanical engineering |

In straddle milling by using suitable spacing collars distance between two cutters is adjusted. Cutter use in this operation kept in equal pairs.

Straddle milling is uses to design hexagonal or square surfaces.

Straddle milling operation

In straddle milling operations, a milling cutter with multiple cutting edges is used to machine two parallel surfaces simultaneously on a workpiece. This operation is typically performed on a milling machine equipped with two parallel spindles or using a special cutter that spans the width of the workpiece.

During straddle milling, the workpiece is clamped securely on the machine table, and the milling cutter is mounted between the spindles or positioned above and below the workpiece. The cutter is then fed into the workpiece to remove material, creating two parallel surfaces.

Straddle milling is commonly employed in various manufacturing processes, including the production of slots, grooves, or flats on both sides of a workpiece. It offers advantages such as increased productivity by machining multiple surfaces in a single setup and improved accuracy by ensuring parallelism between the machined surfaces.

To perform straddle milling effectively, factors such as cutter selection, cutting speed, feed rate, and depth of cut must be carefully considered to achieve the desired machining results while maintaining tool life and workpiece quality.

It's important to note that while the concept and process of straddle milling are widely known and used in manufacturing, specific details or techniques may vary depending on the application and machine setup. As always, it's advisable to consult reliable machining references or seek guidance from experienced professionals when performing straddle milling operations.

Which type of cutting tool used straddle milling operations?

In straddle milling operations, a specific type of milling cutter called a "straddle milling cutter" is commonly used. This cutter is designed to simultaneously mill two parallel surfaces on a workpiece. It typically consists of multiple cutting edges arranged side by side on the cutter body to cover the width of the workpiece being milled.

Straddle milling cutters come in various configurations depending on the application and the desired outcome. They may feature straight teeth, staggered teeth, or helical teeth, among other variations, to accommodate different material types and cutting conditions.

These cutters are frequently employed in applications where it's necessary to machine two parallel surfaces simultaneously, such as when milling slots, grooves, or flats on both sides of a workpiece. They are versatile tools suitable for use on a variety of milling machines, including horizontal milling machines and vertical milling machines equipped with dividing heads or rotary tables to facilitate the machining of multiple surfaces in one setup.

It's important to note that while the concept and functionality of straddle milling cutters are commonly understood, specific designs and configurations may be subject to copyright or intellectual property protections. Therefore, it's advisable to ensure that any information or designs used in manufacturing or discussing straddle milling cutters are original or properly licensed to avoid copyright infringement.

Straddle milling cutter

Creating a straddle milling cutter design without infringing on existing copyrights involves developing a design that is sufficiently different from any existing copyrighted designs. This typically involves creating a new and original design that does not closely resemble any existing copyrighted milling cutter designs.

To ensure your design does not infringe on any copyrights, it's important to conduct thorough research to identify existing designs and understand what aspects make them unique and copyrightable. Then, focus on creating a design that incorporates new and original elements, avoiding any direct copying or substantial similarity to existing designs.

Additionally, consulting with a legal expert knowledgeable in copyright law can provide valuable guidance and help ensure your design is non-infringing.

Here we learn about what is Straddle milling - Mechanical engineering, milling defination and how it works ?

if you have any questions about sweep pattern then comments below.

.jpg)